Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

🔧 Master every flare with precision and confidence!

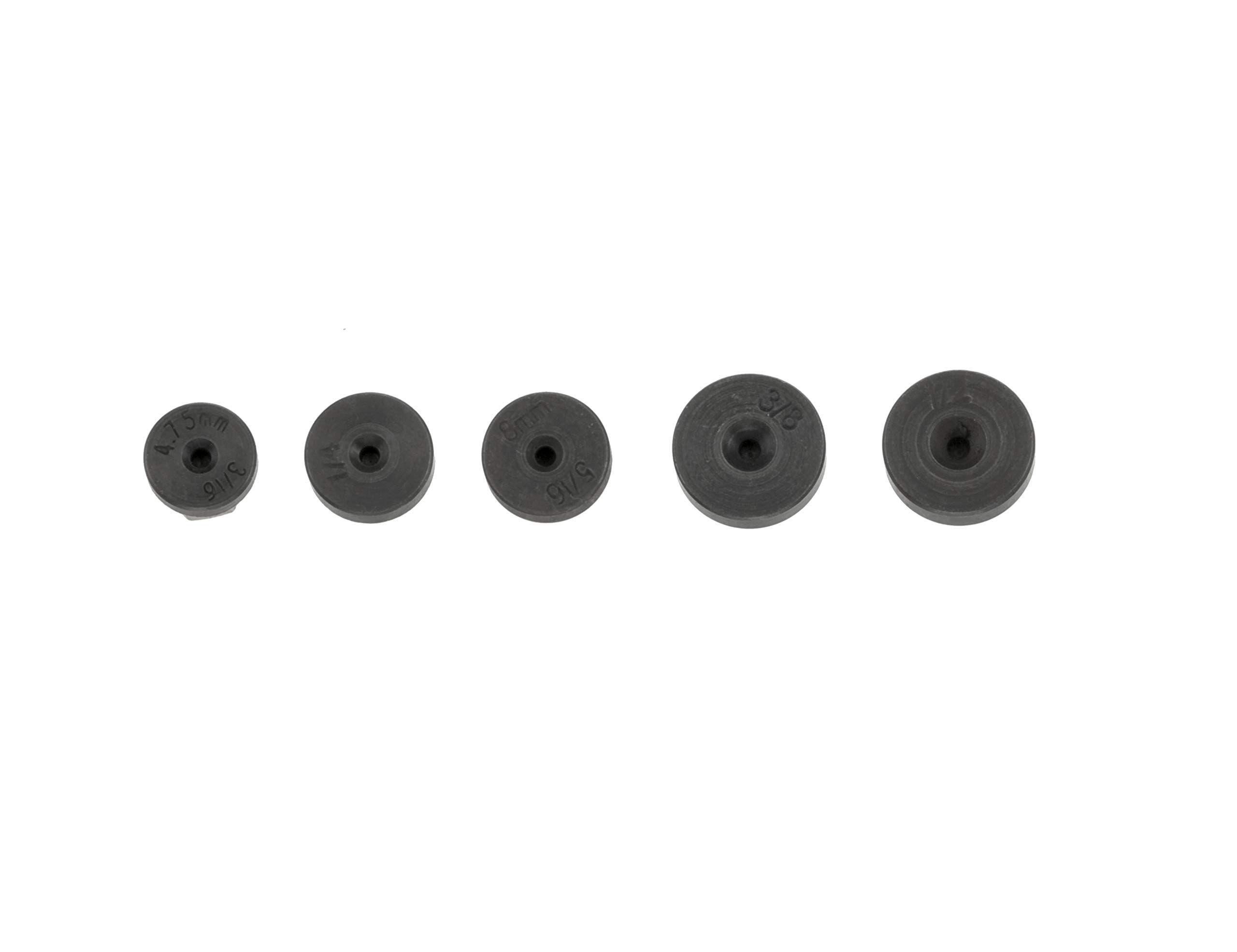

The ARES 18020 Double Flaring Tool Adapter Set includes five precision-sized adapters (3/16" to 1/2") made from durable aluminum with a brass finish. Designed for use with the ARES 18019 Double Flaring Tool, it supports flaring on copper, aluminum, brass, magnesium, and soft steel brake lines. This set ensures reliable, professional results with trusted ARES quality and customer support.

| Size | Double Flaring Tool Adapter Set |

| Material | Aluminum |

| Brand | ARES |

| Color | Copper |

| Item dimensions L x W x H | 3.2 x 0.8 x 3 inches |

| Connector Type | Flare |

| Exterior Finish | Brass |

| Item Weight | 1.6 ounces |

| Number of Pieces | 5 |

| Manufacturer | ARES |

| UPC | 818765020795 |

| Product Dimensions | 3.2 x 0.8 x 3 inches |

| Manufacturer Part Number | 18012 18019 18020 |

S**.

Handy tool.

Works great. It came in handy when I was replacing my brake lines.

P**A

Price and quality.

Good quality tool, easy to use.

M**O

Quality of flaring tool matches that of my Matco one (once the washers are upgraded)

Bought this to replace my Matco one after it started flaring crooked. Functions well! My only complaint is the washers under the thumb nuts that hold the clamp together needed to be upgraded to a higher grade. Quick trip to the hardware store to resolve. I took the 45° flaring tool handle and squeezed one end in a vise multiple times to round it out so that it can be removed from the flaring tool (this is how my Matco one is) I use the handle to give the thumb nuts a little extra torque when tightening, so could be operator error, but the washers flattened out, became oblong, and made seperated the 2 halves a little difficult. Overall quality matches that of my Matco tool, and nice bonus that this kits includes the tube cutter.

V**.

Very easy to use.......

Brakes failed on my 1958 Chevy Fleetside truck due to rusted brake lines. I decided to replace all the brake lines (5 lines) with 3/16" nickel copper tubing. After looking at the many tube flaring tools available I opted for the Ares 18025. Unlike other flaring tools that can handle various size tubing, this is specific only for one size, 3/16". Other tools requires chamfering and cleaning each cut before flaring. This one does not (as long as a proper tube cutting tool is used there should be no problem). The tubing locks firmly into the tool and the dies easily flare the tubing (don't know if the process would be more difficult with steel lines, but the nickel copper lines were easy). The double flares came out perfectly on my first try. While bleeding the brakes I had to re-tighten two of the connections due to leaks. But once that was done the system is nice and tight with no leaks. This was my first attempt at making flares for brake lines and it was an absolute no-brainer with excellent results.

H**E

There's no substitute for the right tool!

Brakes are so critical to safety that you just shouldn't cut corners by using anything but inverted double-flare fittings. That type of flare always seemed complicated and difficult to create but I needed to repair the rear brake lines on my truck so I thought I'd rent the "pro" tool from an auto parts store and do the job right... a big mistake.Their rental tool is basically the same one a plumber uses to make single flare fittings for copper water lines. The only difference is an additional die that's supposed to force the tubing into the center so the next step can turn it down (invert it) to form the double flare. The whole apparatus is awkward to handle, particularly if you're working directly on the vehicle, and it's practically impossible to keep everything aligned and centered. I made multiple attempts on scraps but never got a satisfactory result. No matter how hard I torqued everything down, the final repairs leaked under pressure.My research led me to the ARES 18025 and I can't say enough good things about this tool. My first attempt produced a flare practically identical to a factory fitting (and see photo 12 to compare it to a flare made on the rental tool). Using this tool, I remade the repair and everything came together with no leakage at all.A couple of hints:1) In photo 3 you see I've smoothed the inside of the tubing with the tip of a phillips screwdriver. This makes the inside of the flare smoother.2) Use a drop of oil to lubricate the threads of the die and one on the tubing end for each stage of the flare. Doing so makes the final result more uniform and saves wear on the tool.3) Be sure to run the dies all the way down (see photos 6 & 9), bottoming out the shoulder of die onto the body of the tool. That ensures a complete and uniform flare.I also added a cutaway photo (#13) of the first flare I made with this tool so you can see exactly how the it shapes the tubing into a true inverted double flare fitting.

E**N

Garbage.

Cheap Garbage. 3/16 adapter fell apart after 3 uses.Working on super soft Nickel Copper line. I didn’t even have it all the way down.Clamp, doesn’t clamp around the line, when you tighten it, leaves extra material. Had to use my old one until the adapter broke. Now looking for a replacement.

A**R

Looks used

The pipe cutter looks used. Top of the case has oil mark. I will test the flare out later.

M**R

QUALITY TOOL -- WORTH EVERY PENNY!

In the past, I have used those standard double flaring tools everyone sells with limited success due to the inability to accurately measure the protruding tube, and holding the unit block steady while trying to flare the end. The inventor of this device is a genius! The tool is designed well and is goof-proof. I was able to make numerous perfect double flares on my car without bending the heck out of the line. Also, the tool is small and can make the perfect double flare in the tightest of spaces. I used a ratcheting box wrench to screw in the punch with very little effort. It is great to find a tool that is easy to use and actually works!

Trustpilot

2 days ago

1 month ago